Patient safety

25-Jan-2021

One of the primary goals of healthcare is to use the power of modern medicine and quickly-advancing technology to help improve the quality of peoples’ lives. From sterilization to operation, comprehensive protection of patients in the operating room must be a top priority for every surgeon who is seeking to accomplish that goal.

Hospitals recognize that protecting patients spans significantly further than just washing your hands before surgery. Sanitation is important, but so is the surgical technique that’s used during the operation, so is the microscope, the bandaging, the ventilation and more.

Across the board, hospitals have done a great job at making the safety of their patients a top-priority. But, there are still areas where they can improve to help ensure that every patient that comes into the operating room is being properly cared for and protected.

Surgical blades are one of those areas.

Over the years, the power tools used in the operating room have advanced and adapted to modern healthcare and evolving patient needs. These changes have widely been accepted across the world, but while the tools have been brought into hospitals, the blades that they power are often forgotten or considered an unnecessary “add-on,” like heated seats in a car or extra legroom in a plane.

If patient safety needs to be comprehensive, the surgical blades cannot be ignored.

What good is it if surgeons wash their hands thoroughly and then perform a procedure that results in dead bone and leads to further corrective operations, simply because the wrong tool was used?

The difference between surgical blades may seem small and inconsequential, but in an industry that focuses on the details and accuracy, these small details are incredibly important.

Cutting technology has advanced to the point where it can and does make a perceivable difference in outcomes, and hospitals that are seeking to protect patients and encourage positive results should invest in the best tools for the job across the board.

In this article, we will describe some of the most common ways that surgical blades can impact patient safety and how newer, better blades can protect patients, surgeons and hospitals.

When it comes to orthopaedic surgery, protecting the bones that are being operated on needs to be a top priority, but what many surgeons don’t know is that the bade you’re using can make a dramatic impact on bone health.

We’ll look at two aspects of orthopaedic blades that affect bone health: cutting temperature and blade control. We’ll see how improvements in blade and tool design have addressed these safety concerns.

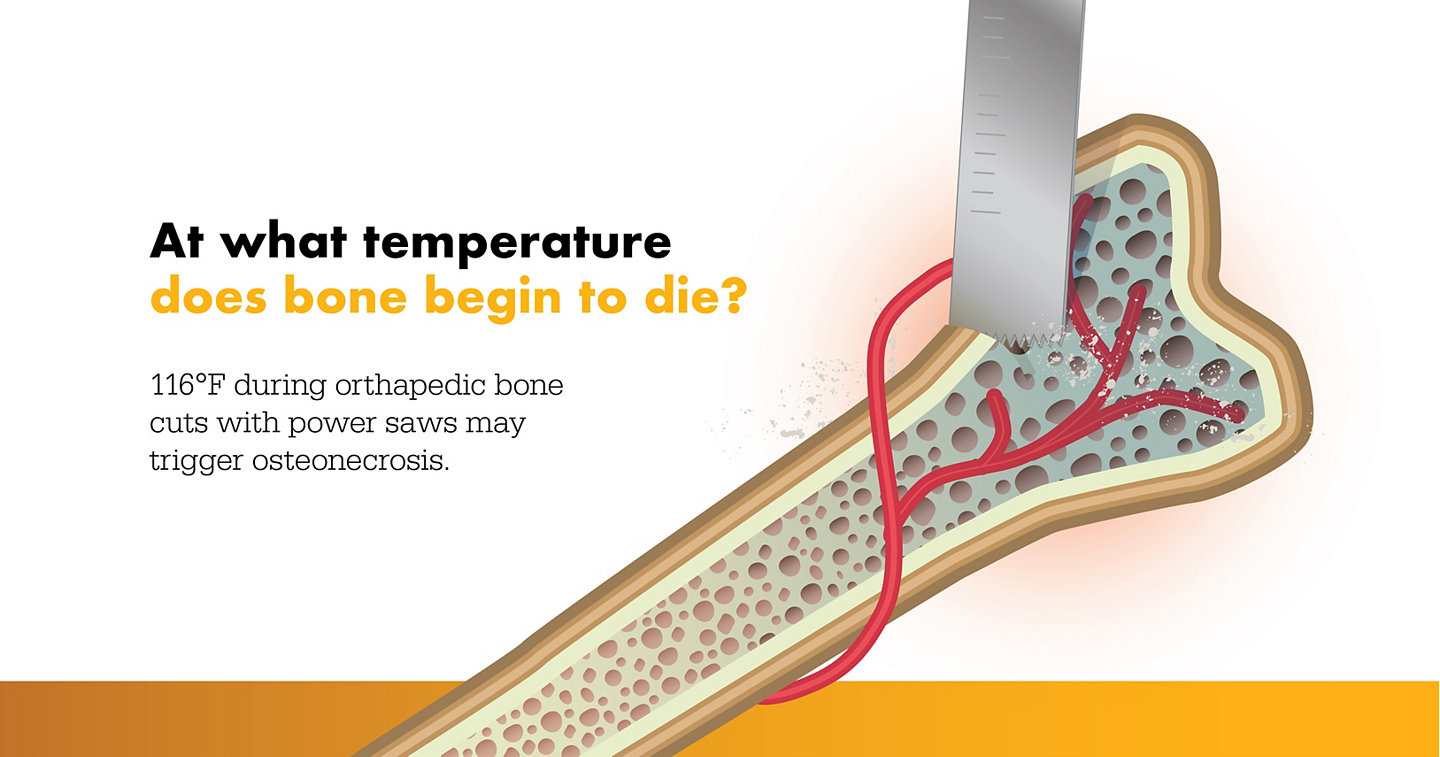

Cutting temperature is an immediate safety concern for surgeons because, when cutting, friction is created when the blade rubs quickly against the bone surface. If left long enough, that heat can actually damage the bone’s blood supply and, in serious cases, even kill the bone (osteonecrosis).

Bone temperatures above 47°C (116.6˚F) during orthopaedic bone cuts with power saws may trigger osteonecrosis and studies have found that many factors can contribute to damaging friction.[1]

The type of saw and blade used plays a significant role in determining the amount of heat that’s generated while cutting, and the speed of cutting determines how long the bone is exposed to that heat. Using the incorrect blade in this scenario can subject the bone to excessive, unsafe levels of heat for extended periods.

Imagine, for example, that you’re about to cut into a delicious T-bone steak, but instead of handing you a steak knife, your server gives you a butter knife. Now, the butter knife can still cut through that steak, but it will require much more time, effort and cutting on your part to do the job that a steak knife could do more quickly and effectively.

This is essentially what happens in operating rooms across the world, just on a much more serious, intricate scale. Surgeons are using blades in their tools that are simply not right for the job, and it forces them to do more work and spend more time doing it, which can put patient safety at risk.

When choosing a knife for dinner, you’ll pick the right one for the job. Similarly, surgeons need to be highly conscientious of their choice in tools and should be looking for blades that are specifically designed to help them manage speed and cutting temperature.

The Stryker Precision Oscillating Tip Saw has two speeds, standard (12KCPM) and fast (16KCPM). Its stationary blade shaft improves visibility for the surgeon, reduces damage to surrounding tissue and makes it ideal for MIS (minimally invasive surgery).

The new shorter (90mm) Precision Falcon cartridge blade, combined with the fast speed on the Stryker Precision Oscillating Tip Saw, cuts 58% faster. The blade’s shorter length contributes to a stiffness increase by 42% and gives increased control.2 This combination of saw and blade promises better results for accuracy and speed, but with the powered cutting, speed, as always, brings the concern of heat generation at the bone site.

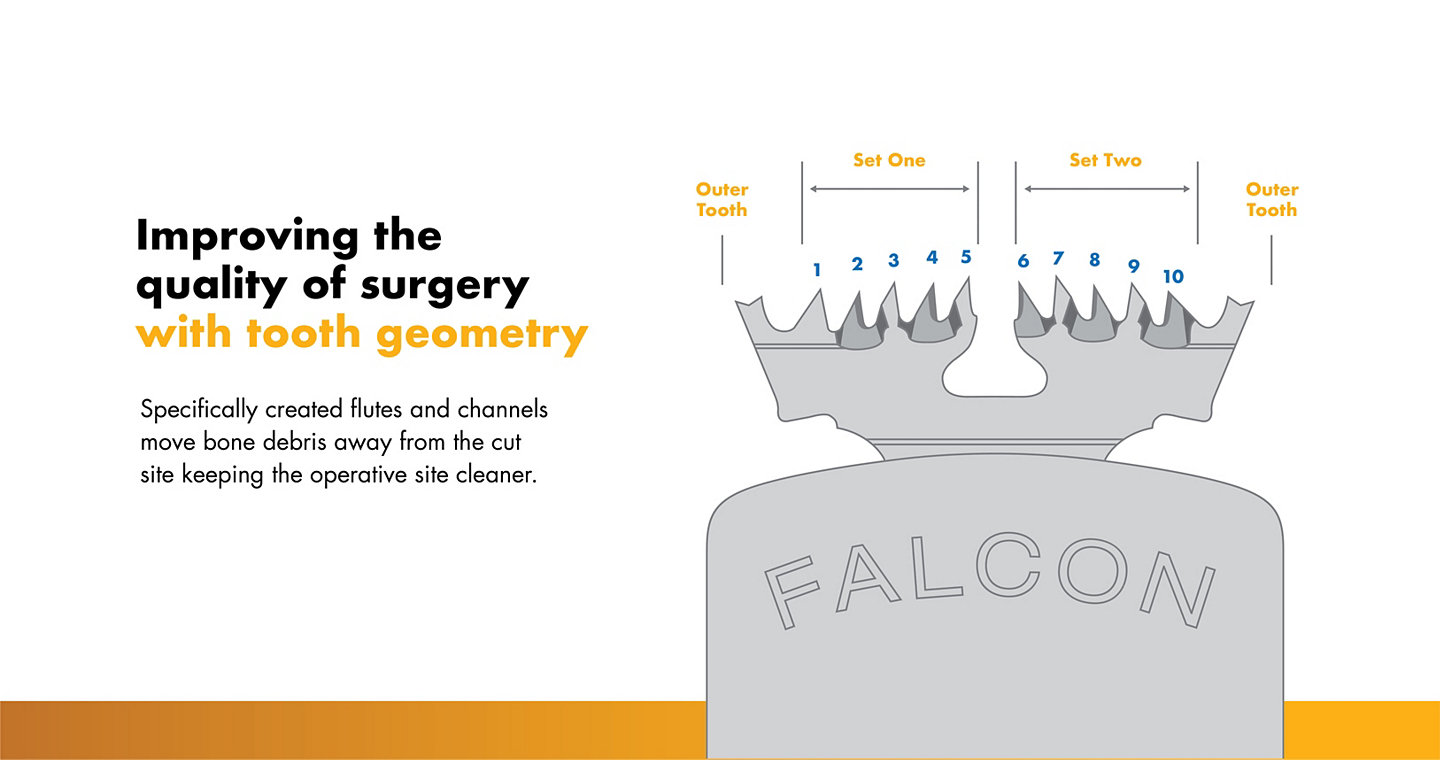

Blades may seem simple and, ultimately, their intended purpose is fairly rudimentary, but many blades, especially those used in surgery, have very complex designs and functions. The type of blade tooth geometry, the blade length, operation, speed, removal of debris and other factors drive the choice of blades and tools.

While looking at how blades can impact patient safety in the surgical suite, we also need to see control aspects, specifically precision, excursion, and chatter. Surgery is an exact science, and when considering a blade that will be used on a patient’s body, it’s absolutely essential that it obeys the surgeon in exactness and in motion.

Excursion is a term that’s used to describe the range of repeated movement in a medical device, like a surgical blade. Excursion is an important item to measure because the greater a blade’s excursion, the more difficult it can be to control, especially in intricate and delicate locationswhere accuracy is absolutely critical.

For example, think about an electric toothbrush which has a very low level of excursion. It’s relatively easy to control inside your mouth and you can be very quick and accurate, getting it exactly where you want it to go. Now, think about an industrial jackhammer, which has a much larger excursion and is much harder to control.

In a sense, the same idea is true for surgical blades. A toothbrush and an industrial jackhammer are used for different jobs and can both incredibly effective when used in the right context. In the same way, a blade with a larger excursion can be helpful in certain operations, while a blade with a smaller excursion is valuable for others.

However, using the improper tool in the improper context is, in the best-case scenario, unhelpful, and in the worst case, can have an impact on outcomes and patient safety.

A study evaluating accuracy and excursion of blades (the extent of blade movement) used for total knee arthroplasty (TKA) compared results from two types of blades: a conventional oscillating saw blade (Stryker System 6 Sagittal Saw), and an oscillating tip saw blade (Stryker Precision Sagittal Saw).[3]

The study’s key indication is that excursion is related to the saw blade length and the distance of the oscillation from the end of the blade.

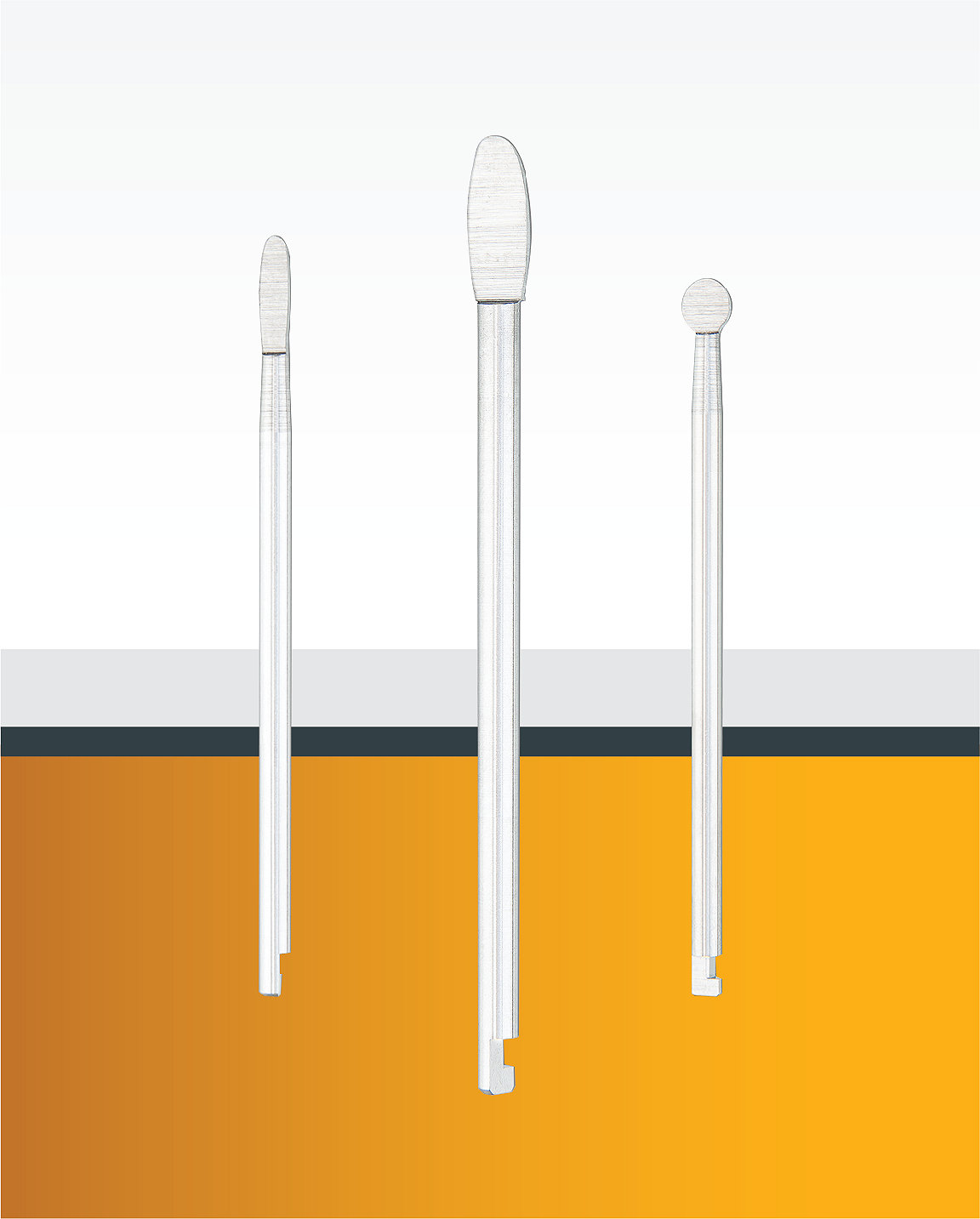

Performance Series Blades

Chip Clearance

Stryker Precision Oscillating Tip Saw

Chip Clearance

The conventional saw blade oscillates from the hilt of the saw, compared to the oscillating tip saw, which evidenced little excursion.

Minimal dye markings with the oscillating tip blade suggested less impaction for the soft tissue around the knee, which allowed for a more straightforward recovery.

Better outcomes are suggested with minimal excursion, since damage to the extensor mechanism, neurovascular bundle, and medial collateral ligament during a TKA procedure can lead to complete joint failure.

Incidentally, the oscillating tip saw system has been measured to be quieter than the conventional oscillating saw blade system, making surgery safer for the surgical team as well.[4]

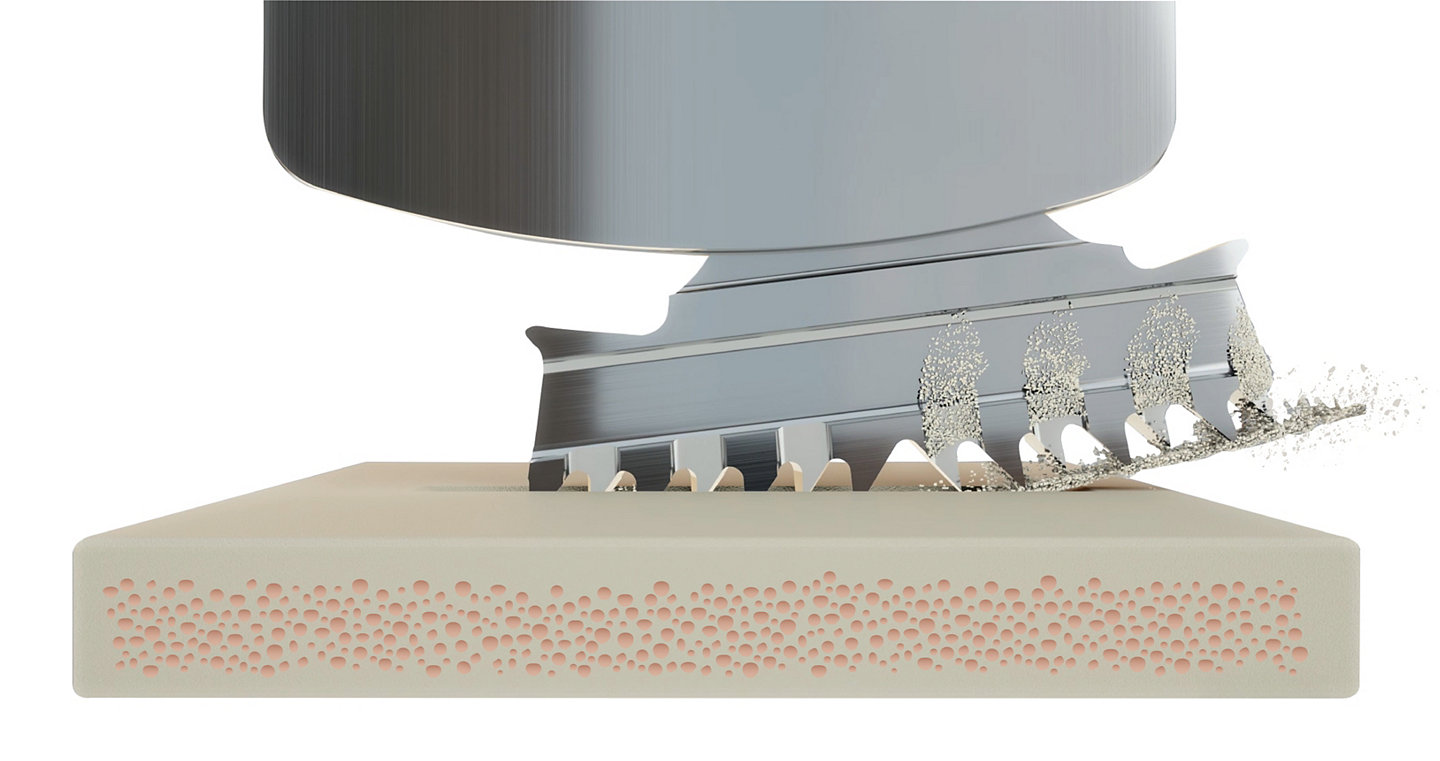

Beyond the well-known concern for metal debris from metal-on-metal hip replacements, orthopaedic surgical cutting incurs the risk of minuscule fragments of metal getting sheared from accidentally scraping the cutting blocks or guides with the surgical blade.

One study suggested about 500,000 metal particles can fall into the body from a single blade during an operation and, since many tools are typically used in orthopaedic surgeries, that many millions of metal particles from blade and blocks could be generated in a single TKA.[5]

The type of blade (and saw) used is a major factor in the precision of each cut, and in just how much debris is generated. Because of the difficulty of removing metal debris from a joint site during actual surgery, this wayward debris can enter the joint and increase joint wear, as well as lead to bone loss. The spray of debris during cutting also presents a hazard to both patient and surgical staff.

A recent study compared the debris generated in surgical procedures with different tools. The study, using porcine cadaveric knee joints, was designed to approximate TKA, and one experienced orthopedic surgeon performed all resections.[6]

This study compared two cutting systems: System 5 sagittal saw with the standard dual-cut oscillating blade, and the System 6 oscillating tip saw with Stryker Precision oscillating tip cartridge.

Metal debris was carefully collected and measured after each simulated TKA, and for the standard dual-cut oscillating blade averaged 12.741mg. The Stryker Precision oscillating tip cartridge procedures averaged 2.021 mg of debris, an 84% reduction.

%2020?$max_width_1440$)

The study suggests the oscillating tip saws offer superior control on TKA procedures and helps keep surgeons from accidentally hitting the metal guards or blocks, which can create metal debris. This improved saw system provides measurable gains in instrument control. It also illustrates that risk to the patient (foreign-body reaction) and surgical staff can be reduced with the best tools.

Chatter, or blade vibration or rattling, is another issue with surgical blades that directly affects blade control. The problem of chatter is exceptionally common and it can cause serious damage, especially in small bone operations. Unstable cutting and producing uneven surfaces can jeopardize the results of many procedures.

Chatter is a serious issue in orthopaedic surgeries, especially those that involve working on small, more delicate bones like those in the face, wrists or ankles.

Small bone blades are not designed to cut deeply in one pass, lest the chamfers of the bur fill with debris that cannot be discharged and which can affect the instrument’s stability. Jumping or stuttering of a cutting tool can be due to cutting too deeply and clogging bur grooves with a mixture of bone and tissue of varying weights, causing the bur head to rattle. It could also be caused by moving the instrument unevenly, or drilling with irregular force or speed.

Chatter causes inaccuracy of cutting and less desirable results.

Stryker produces small bone blades with specifically patented burs with anti-chatter characteristics built into the design. These small bone blades move bone debris up the channels or flutes of the rotating bur during cutting. The flute geometry allows debris to travel away from the cutting surface and away from the cutting tool while it is being utilized, allowing for the blade to remain clean and a reduction in chatter.

In addition to the benefits provided by unique design of the Stryker blades, the Stryker burs, in turn, enable a subtle level of control over the treatment site that preserves as much healthy bone and tissue as possible. Together, these Stryker tools offer enhanced benefits for many major joint procedures, including TKA, total shoulder, and total ankle.

Avoiding chatter means having better control of the cutting process and more precise results. Stryker’s tool systems offer exceptional control and thus significantly reduce the risk of chatter and concomitant harm.

Each surgical application calls for wise choice of tools to maximize patient safety. The wrong device slows down progress and puts unnecessary burdens on the surgeon. The high stakes of the surgical suite demand highly-skilled practitioners using the best tools available, all to keep each patient safe.

[1] Augustin G, Zigman T, Davila S, Udilljak T, Staroveski T, Brezak D, Babic S. Cortical bone drilling and thermal osteonecrosis, Clin Biomech (Bristol, Avon). 2012 May;27(4):313-25. https://www.ncbi.nlm.nih.gov/pubmed/22071428.

[2] https://pdf.medicalexpo.com/pdf/stryker/system-7-precision/70192-129312.html, accessed January 15th, 2020.

[3] Wetzel RJ, Shah RR, Puri L. Demonstration of saw blade accuracy and excursion: a cadaveric comparions study of blade types used in total knee arthroplasty. J Arthoplasty, 2013 Jun;28(6):985-7. https://www.ncbi.nlm.nih.gov/pubmed/23523505

[4] Peters MP, Feczko PZ, Tsang K, van Rietbergen B, Arts JJ, Emans PJ. Noise exposure in TKA surgery; oscillating tip saw systems vs. oscillating blade saw systems, J Arthroplasty. 2016 Dec;31(12):2773-2777, https://www.ncbi.nlm.nih.gov/pubmed/27394075.

[5] Gotterson PR, Nusem I., Pearcy MJ, Crawford RW. Metal debris from bony resection in knee arthroplasty – is it an issue? Acta Orthopaedica 76, no. 4 (2005) https://www.tandfonline.com/doi/full/10.1080/17453670510041448.

[6] Sarah E. Sydney, BEng; Simon A. Pickering, MD, FRCS (Eng), FRCS (Orth); Cameron G.R. Bell, PhD; Ross Crawford, MBBS, FRACS, DPhil (Oxon). Reducing Metal Debris Generation During Total Knee Arthroplasty. Orthopedics, 2007; 30(12): 999-1000. https://www.healio.com/orthopedics/knee/journals/ortho/2007-12-30-12/%7B03131112-b352-4ee1-9103-4b7d7b79f546%7D/reducing-metal-debris-generation-during-total-knee-arthroplasty

2021-28366