Patented technology

11-Dec-2020

Spurred on by the rapid advance of technology, the healthcare industry is seeing advancement like never before. In the past, change has typically happened slowly as our knowledge of the human body and the procedures needed to address issues within it has evolved.

But, in recent years, this has all changed. There are new phones every year with faster processors, better cameras and smarter artificial intelligence integration, our cars can park themselves and see our blind spots, search engines, social networks, mass retailers are using machine learning to more accurately manage requests and searches.

We are constantly surrounded by changing technology and nowhere has that been more apparent than in the field of healthcare.

Medical technology has advanced to the micro level where seemingly imperceptible differences in tools can make a dramatic difference in surgical outcomes.

Surgical blades are no exception.

Stryker engineers have worked diligently, in producing 15 generations of surgical instruments, to address the many cutting challenges facing surgeons, especially the physics of cutting related to temperature and control:

1. Bone cutting temperature

Bone cutting results in varying levels of heat. Excessive bone heat is known to lead to osteonecrosis, or bone death, an enemy of a successful orthopaedic procedure. Positive results depend on healthy and growing bone to support implants, hold screws and plates in repairs, to promote healing and return to proper function.

2. Blade control

Blade control is crucial in bone cutting, in any procedure, but especially in small bone surgery, lest the cut is off-target or too deep. Additionally, being able to control the blade prevents avoidable metal debris from abrading off the cutting blocks or guards and into the body. Trapped particles in the surgical site can cause foreign body reaction, or if located in a joint, can cause additional wear. Designed to work together, the oscillating tip saw and corresponding blade pairing have proven to significantly reduce unwanted blade excursion.

3. Bone cutting fragments

Blades must be designed to allow bone cutting fragments to flow away from the cutting area and not to clog the teeth. Stryker holds the utility patent on a blade with a central clearance area that is very effective, yet maintains the integrity of the blade. The blade surfaces are also electropolished for a smooth and low-friction finish.

4. Cutting teeth

The cutting teeth are arranged to improve cutting control and stability, debris flow and heat generation. Some tooth configurations are ideal for one application over another.

The resulting blade designs address these issues and many more. Stryker saw blades are patented; they are well-represented among the 7,784 patents which Stryker owned worldwide as of 2018. Some blades are covered by as many as 11 patents, revealing the advanced nature of these cutting edges.

Patents rightfully guard Stryker’s R & D investments and products from competitors who haven’t and cannot make the same advancements.

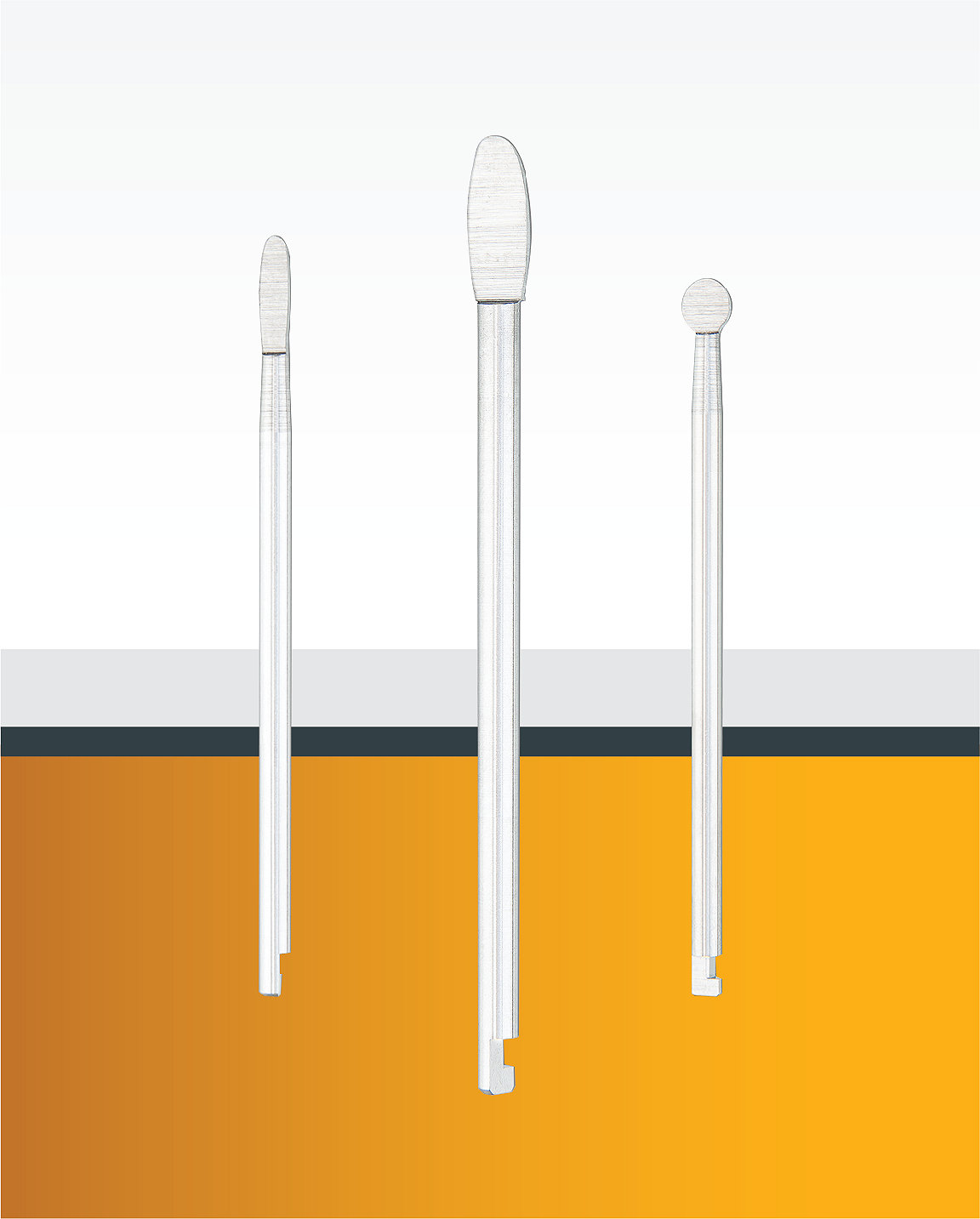

Let’s compare two of the blades designed for Stryker System 7 Precision Oscillating Tip Saws. The blades are both produced from stainless steel that has been heat-treated in a controlled environment for both material hardness and ductility. The teeth edges are precision cut by CNC controlled machinery and then electropolished to produce low friction surfaces.

Standard Precision (6525-127-105) blade has two sets of seven pitch (or close-set) outward facing teeth on each blade.

This configuration of 14 teeth produces smooth cutting at a controlled pace. Because the cutting edges face out, the bone particles flow to the outside of the blade during cutting, reducing potential clogging. When the blade cuts to the right, debris flows to the right.

There are also ground slots between each tooth that allow cut particles to move away from the cutting edges. These slots feed a central longitudinal channel that permits cut particles to flow away to the sides of the blade.

Comparing this with the Precision Falcon (6725-137-105) cartridge tooth configuration, we find that it has two sets of five inward-facing teeth with an additional tooth on each end. These teeth have a larger distance, or pitch, between them that permits faster cutting.

A central clearance area sits between and below the teeth. When the blade moves to the right, the teeth on the left do the cutting, and debris moves along the blade to the center, pushing particles into the cutout in the blade center. When the blade moves to the left, the process is reversed. Again, ground slots between and below each tooth channel cut debris away from teeth, and the blade is thinner below the teeth to let debris flow to the outside of the blade.

These two blades provide significant differences in cutting and are favored for their strengths in different applications. The Standard Precision blade has been preferred by some surgeons for High Tibia Osteotomy (HTO) procedures, where denser bone may be encountered.

Laboratory testing has shown that the Falcon teeth geometry produces a faster, lower temperature cut on synthetic materials. Anecdotally, some preference may for Falcon blades for use in a TKA or THA, as the coarser pitch seems especially appropriate for softer bone.

Both blades are verified safe and effective, but its important for surgeons to ensure that they're using the right tool for the job.

Here we have highlighted select features of the patents covering the blades and cartridges we compared above:

Patent US7497860B2: Surgical sagittal saw including a handpiece (a motorized cutting tool) and a removable blade assembly, the blade assembly including a guide bar, a blade head capable of oscillating movement and a drive rod for actuating the blade head, granted 2004.

The specific advantages of oscillating saw tip motion, including control, stiffness, exact range of motion, and clearance, are described and protected in this patent.

Because the oscillation occurs at the tip of the saw, rather than the hilt, the range of motion is more specific. The oscillating mechanism is designed to operate with reduced friction and lower heat in its motion, and engage in bone smoothly.

This addresses the problem of a saw bucking or kicking when encountering tough bone by providing a smooth cutting action, and allows bone to be approached at a low angle as is necessary in some procedures. It also removes the problem of a cutting system that seems to bog down or need more pressure from the surgeon, which could lead to dangerous inaccuracies in cutting.

Patent US7744616B2: Surgical sagittal saw blade with angled teeth and chip catchment and reciprocating saw blade with broached teeth, granted 2010.

On some surgical sagittal saw blades, the individual teeth are arranged with cutting edges facing inward. This means that each time the teeth encounter bone, they reduce kicking and cut more smoothly. Cut debris flows from the teeth to a void space behind the teeth that serves as a chip catchment area. Since debris flows away, the blade is more efficient.

The reciprocating saw blade teeth are not arranged in a straight line. This angled tooth geometry puts the later teeth in a deeper cutting position. This increases the amount of material the later teeth can remove and improves overall cutting efficiency.

For example, Stryker System 6 Sagittal Blade 6125-100-110 is covered by this patent:

6125-100-110 is a heavy-duty blade with beveled edges that are intended to reduce the likelihood of soft tissue damage. These edges also help reduce wear debris within the cutting block, especially with single-use cutting blocks. The concave tooth design increases cutting stability by engaging fewer teeth at one time. The inner teeth feed bone chips into a center chip clearance area, and this design makes for a 20% faster cut.

Patent US8043292B2: Surgical sagittal saw blade including a guide bar, a blade head, and drive rods for pivoting the blade head, granted 2011.

The blade mounts to the guide bar to pivot around a pivot point, its teeth extending beyond. Drive rods extend from the blade and connect with the saw. When turned on, the drive rods move in reverse reciprocation, causing the blade to oscillate only at the tip of the saw. This increases cut control, and makes it safe enough for minimally invasive surgeries.

A capture pin holds the blade in the cutting guide for accuracy and stability of cut.

The patent describes the mechanism of the oscillating tip saw. The long, thin blade, guide and drive rods isolate the cutting motion right to the tip of the blade.

- This reduces accidental tissue damage

- This reaches into a joint area that has limited access

- It also reduces metal particle debris from errant blades, and friction and resistance from the blade motion.

Patent US8323285B2: Method for manufacturing a surgical saw blade with a blade head and raised boss around which the blade head pivots, granted 2012.

This describes the order progression of punching and welding specific parts together for best results in constructing the blade assembly.

Patent US8348951B2: Sagittal saw blade with a static bar and moving drive bar and blade crown, the bar having secondary openings, granted 2013.

The blade bar is static, and attaches to the saw. The blade bar contains drive rods that oscillate the blade crown.

Secondary openings in the blade assembly allow release of any trapped cut material.

The patent also describes numerous features of the saw, as well as the RFID connection between saw and blade, used in surgical navigation systems. The saw can be adapted for various surgical uses with assorted attachments.

Patent US8444647B2: Surgical sagittal saw blade with a static bar and a pivoting blade head, the bar shaped to facilitate holding the blade to the complementary saw, granted 2013.

The blade bar tapers outwardly at its near end, to better join with the saw.

Saw coupling is designed for easy, toolless exchange of attachments. Saw is shaped for ease of use; power options include battery, electrical cord, air hose, or fluid line.

Patent US8696673B2: Surgical sagittal saw blade with a biasing assembly that urges the blade assembly used with the saw away from the saw head, granted 2014.

The saw includes a saw head, over which the blade assembly is seated. The coupling and biasing member have a push-pull relationship:

The coupling assembly easily unlocks, rotates, receives a new attachment, realigns, and relocks.

A biasing member places a force on the bar that urges the bar away from the saw head. When the saw is utilized, the coupling assembly acts against the biased force to hold the blade static. When the saw is off, the biasing force helps remove the blade easily from the saw.

Location of holes in blade and bar assembly virtually guarantee that cutting debris will not clog and impede the cutting process.

Patent US9072526B2: Surgical sagittal saw blade assembly that includes a guide bar with bottom, inner and outer bars and a blade head that pivots around the inner bar, granted 2015.

Cutting guides or blocks of varying sizes and shapes are used to make precise cuts to prepare bones for implants. Because of the unique oscillating saw tip, these cuts are more precise, the blocks are grazed less frequently, less pressure is needed to utilize the saw so it is easier on the surgeon, and less wear and resistance forms within the blade assembly because of low friction inner design.

The capture pin holds the blade along the guide, so the surgeon does not have to maintain the positioning by hand.

Patent US9060783B2: Surgical sagittal saw for actuating a saw blade with an oscillating head, the saw having a coupling assembly for releaseably holding the saw blade, granted 2015.

This describes the clever movement of the clamp rod on the sagittal saw’s rod head, that permits easy exchange of attachments, such as in the surgical suite.

Patent US9439655B2: Surgical sagittal saw and blade cartridge, the blade cartridge having reinforcing ribs integral with the blade bar, granted 2016.

Ribs running the length of the blade cartridge reduce flexing or skiving while cutting. The ribs are positioned to both add stiffness but not interfere with the ability of the surgeon to fit the saw in a resection guide.

Patent US9445822B2: Method of assembling the oscillating assembly of a surgical sagittal saw, 2016.

This again describes in detail the essential features of the saw, coupling, and cartridge. It specifies the steps to correctly assemble a saw.

We’ve glimpsed some of the complex innovations of Stryker saw blades. These 11 patents describe hundreds of pages of technical advancements that are not available to competitors.

Competitors are attempting to copy and sell cheaper saw blades, but they’re not really producing anything that Stryker hasn’t already pioneered.

By law, they are not able to include the subtle nuances that resolve surgical cutting challenges, because those innovations are protected. In attempting to market a cheaper blade, they have necessarily lost much of the blade value, because Stryker research and development conceived of and patented these improvements first.

When it comes to blade design, Stryker is defining and directing the industry.

https://www.odtmag.com/heaps/view/6173

Patents:

US7497860B2 https://patents.google.com/patent/US7497860B2/en

US7744616B2 https://patents.google.com/patent/US7744616B2/en

US8043292B2 https://patents.google.com/patent/US8043292B2/en

US8323285B2 https://patents.google.com/patent/US8323285B2/en

US8348951B2 https://patents.google.com/patent/US8348951B2/en

US8444647B2 https://patents.google.com/patent/US8444647B2/en

US8696673B2 https://patents.google.com/patent/US8696673/un

US9072526B2 https://patents.google.com/patent/US9072526B2/en

US9060783B2 https://patents.google.com/patent/US9060783B2/en

US9439655B2 https://patents.google.com/patent/US9439655

US9445822B2 https://patents.google.com/patent/US9445822/pt-PT