MEDPOR Customized Implant

Overview

MEDPOR has been a trusted name in the industry since 1985, with hundreds of thousands of procedures performed, and more than 150 published reports in reconstructive, cranial, oculoplastic, and cosmetic applications.1

Our MEDPOR product line provides you an array of porous polyethylene solutions for your reconstruction and augmentation needs. We understand that biocompatibility characteristics of implants are paramount to help surgeons achieve positive patient outcomes. The omni-directional pore structure of our polyethylene implants may increase implant acceptance by allowing the patient‘s native tissue to integrate with the implant. In addition to our comprehensive line of stock MEDPOR implants, we offer CT-based patient specific implants, putting the implant design in your hands.

Precise fit. Proven material.

Features and benefits

Modification

Implant may be contoured with a scalpel or burr.2

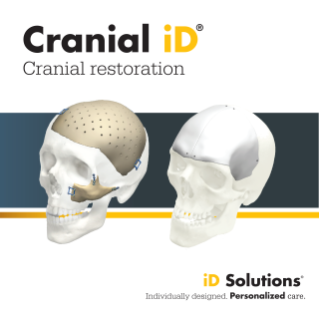

Fit options

Designed and manufactured to the surgeon’s preference, with inlay and flange (removes need for plates) options.

Tissue in-growth

The interconnecting, omni-directional pore structure of MEDPOR may allow for fibrovascular in-growth and integration of the patient’s tissue.3,4

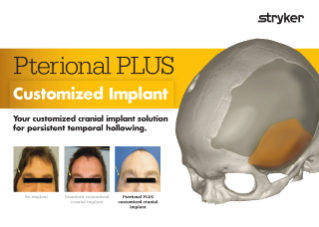

Onlay & augmentation

MEDPOR implants are indicated for onlay/augmentation applications in cranial, midface, and mandible bone.

Resources

Clinical evidence

Craniectomy defects following resection of calvarial lesions are most often reconstructed using on-table manufacturing. With the advent of computer-aided design/manufacturing and customized craniofacial implants (CCIs), there seems to be more suited alternatives. In this study, the authors report their institutional experience and outcome using immediate, single-stage, CCI-based reconstruction for benign and malignant skull neoplasm defects.

METHODS

A retrospective review of a prospectively maintained database of all implant cranioplasties performed between 2011 and 2014, by a single craniofacial surgeon at a tertiary academic medical institution was performed. Preoperative and postoperative computed tomography scans with 3D reconstruction were performed for the purpose of assessing adequate resection and reconstructive outcomes. Primary endpoints included length of surgery, predicted defect versus postoperative implant surface area, contour irregularities, and complications.

RESULTS

Of the 108 patients with cranioplasty identified, 7 patients were found to undergo immediate CCI-based reconstruction for calvarial neoplasms; 4 patients (4/7, 57%) presented with malignant pathology. All defects were >5 cm2. As compared with their original size, all implants were modified intraoperatively between 0.2% and 40.8%, with a mean of 13.8%. With follow-up ranging between 1 and 16 months, there were no implant-related complications identified. The immediate and long-term aesthetic results, as well as patient satisfaction, were ideal.

CONCLUSION

With this preliminary experience, the authors have successfully demonstrated that immediate customized implant reconstructive techniques, by way of intraoperative modification, are both safe and feasible for benign and malignant skull neoplasms. The authors believe that with wider acceptance of this multidisciplinary approach and increased surgeon familiarity, this technique will soon become the reconstructive standard of care.

BACKGROUND

Although materials for secondary cranial reconstruction have evolved with time, the overall approach in terms of bone flap/implantreconstruction after necessary delay has remained constant.

OBJECTIVE

To present our cases series of 50 consecutive secondary cranial reconstruction patients and to describe a multidisciplinarycranioplasty approach developed to reduce morbidity, to minimize infection, and to improve aesthetic appearance.

METHODS

Standard technique teaches us to place the bone flap and/or alloplastic implant directly over the dura or dural protectant after scalp flap re-elevation. However, this procedure is fraught with high complication rates, including infection. While raising the previously incised scalp flap overlying the full-thickness calvarial defect, the dissection is performed within the loose areolar tissue plane beneath the galea aponeurosis, thus leaving vascularized pericranium intact over the dura.

RESULTS

A total of 50 consecutive patients were treated by the senior author encompassing 46 cranioplasties using the pericranial-onlayapproach, along with 4 isolated temporal soft tissue reconstructions with liquid poly-methyl-methacrylate. Of the 46 cranioplasties (> 5 cm), only 1 autologous bone flap developed deep infection necessitating bone flap removal (1 of 46, 2.17%; 95% confidence interval, 0.003-11.3). None of the alloplastic custom implants placed have developed any infection requiring removal.

CONCLUSION

This multidisciplinary approach illustrated in our case series, including our "pericranial-onlay" technique described here for the first time, has the potential to improve patient outcomes, to decrease perioperative morbidity, and to minimize costs associated with postoperative infections after secondary cranial reconstruction.

Related products

High Speed Drills

The most comprehensive and customizable neurosurgical high speed drill platform just grew stronger. With mechanics, motors and attachments, Signature 2 Portfolio aims to provide the exact tool and touch you want with the speed, power and durability you need.

Learn moreRequest information

1. Stryker, 2024, MEDPOR Clinical Evaluation Report Version AA.5, D0000060201CMF.

2. Wellisz, T., Kanel, G., & Anooshian, R. (1993). Characteristics of the Tissue-Response to Medpor Porous Polyethylene Implants in the Human Facial Skeleton. Journal of Long-Term Effects of Medical Implants, 3(3), 223-235. Niechajev, I. (1999). Porous polyethylene implants for nasal reconstruction: clinical and histologic studies. Aesthetic Plast Surg, 23(6), 395-402.

3. Niechajev I. Porous polyethylene implants for nasal reconstruction: clinical and histologic studies. Aesthetic Plast Surg. 1999 Nov-Dec;23(6):395-402.

4. Wellisz, T; Kanel, G and Anooshian, RV. Characteristics of the Tissue-Response to MEDPOR Porous Polyethylene Implants in the Human Facial Skeleton. J Long Term Eff Med Implants. 1993;3: 223-235.

CMF-MEDM-SYK-1966795_REV-0