Modular Dual Mobility

Mobile Bearing Hip System

Dislocation is one of the most common causes of THA failure in both primary and revision procedures.1-4 Modular Dual Mobility (MDM) is designed to help prevent dislocation and assist your operative goals of stability, longevity, and advanced fixation for fractures, primary or revision total hip arthroplasty cases.

Key benefits

Stability

*Although resurfacing type shells have lower jump heights, they have the greatest ROM which is needed when the native femoral neck is retained.

The X3 polyethylene inserts of the MDM system are available in large sizes offering increased jump distance – the distance the femoral head must travel to dislocate.1 The greater the jump distance, the greater the stability of the hip.7

When compared to a conventional THA with a 36mm femoral head, MDM offers a 59% increase in jump distance.5,8

Versatility

MDM is a versatile bearing option, as its indications include both primary and revision cases.1-4 MDM utilizes the Trident Innerchange Locking Mechanism, allowing surgeons intraoperative flexibility.

MDM X3 is compatible with Trident, Trident II and Restoration Anatomic acetabular components, offering surgeons a choice of fixation surfaces and screw hole configurations.

Longevity

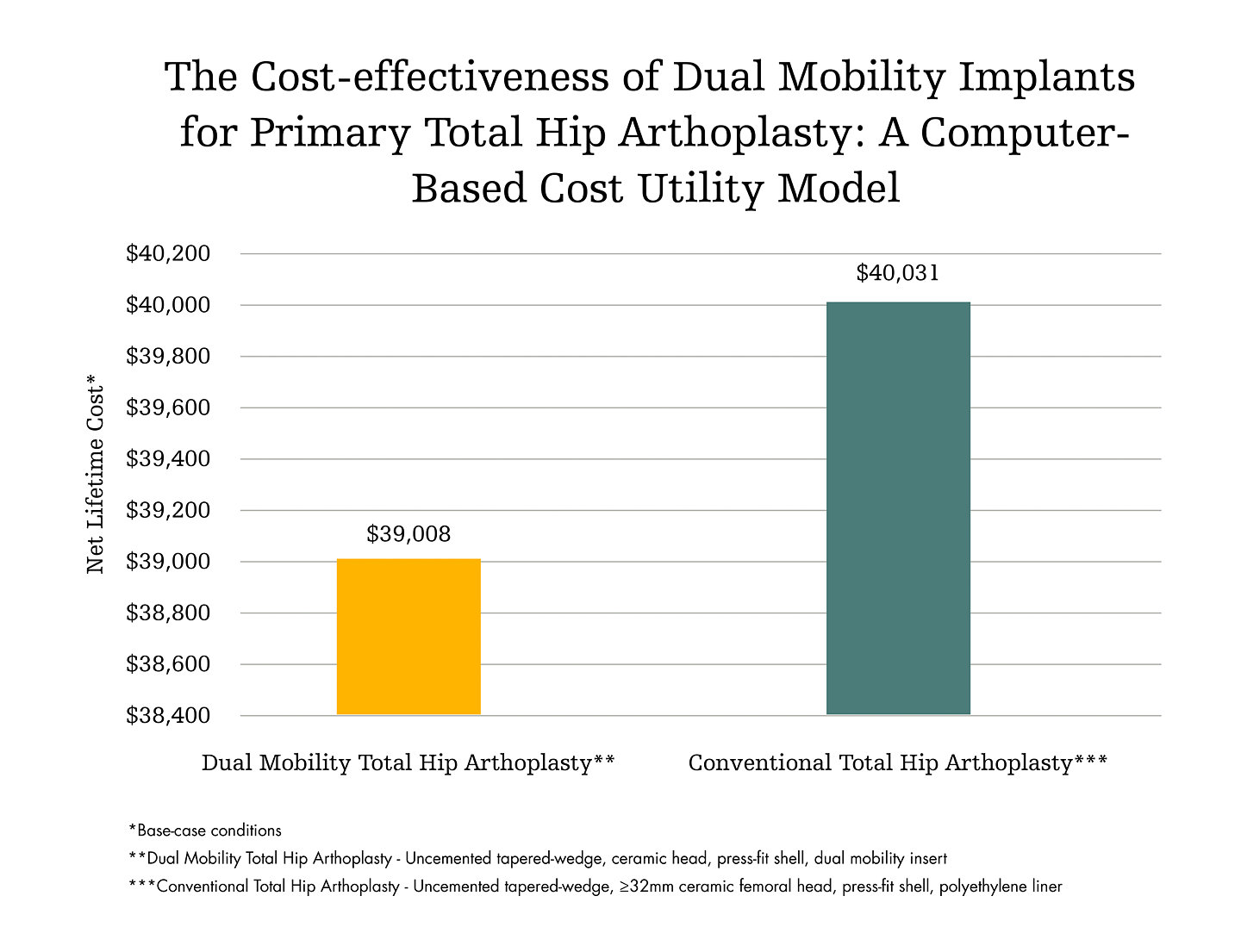

Cost-effective

Modular Dual Mobility (MDM), the most studied modular dual mobility implant in literature.

“Dual Mobility demonstrated improved PROMS and lower rates of dislocation, readmission and revision.”

In a 27-center retrospective study of 664 dual mobility vs. 218 fixed bearings, dual mobility demonstrated improved PROMs and lower rates of dislocation, readmission and revision18

“4x reduced incidence of dislocation.”

In a retrospective review of 267 patients who underwent revision, even with a selection bias of using dual mobility for patients at high risk of instability, patients who received an MDM bearing had a 4x reduced incidence of dislocation (2.1%, vs. 8.7% for conventional polyethylene single bearing, P=0.067) at the mean follow-up of 37.8 months19

“Excellent clinical outcomes and patient-reported outcomes at seven-years minimum follow-up (7 - 8.5 yrs.) with zero cup failures in a cohort of 143 patients.”

Excellent clinical outcomes and patient-reported outcomes at seven-years minimum follow-up (7 - 8.5 yrs.) with zero cup failures in a cohort of 143 patients17

Listen to Dr. Geoffrey Westrich talk about the economic value and applications for Modular Dual Mobility.

References:

- Epinette, J. et al. Early experience with dual mobility acetabular systems featuring highly crosslinked polyethylene liners for primary hip arthroplasty in patients under fifty-five years of age: an international multi-centre preliminary study. International orthopaedics (SICOT). Sept. 2016 DOI 10.1007/s00264-016-3367-0.

- Jauregui, J. et al. Dual mobility cups: an effective prosthesis in revision total hip arthroplasties for preventing dislocations. Hip Int. 2016 Feb 8;26(1):57-61. doi: 10.5301/ hipint.5000295.

- Mont, MA. et al. The Use of Dual-Mobility Bearings in Difficult Hip Arthroplasty Reconstructive Cases. Surg Technol Int. 2011 Dec.; 21:234-40.

- Abdel, M., et al. Dual-Mobility Constructs in Revision THA Reduced Dislocation, Re-Revision & Reoperation Compared to Large Femoral Heads. Hip Society 2017 Otto Aufranc Award.

- Heffernan, C., Bhimji, S.,Macintyre, J., et al. (2011). Development and Validation of a Novel Modular Dual Mobility Hip Bearing. ORS Annual Meeting Poster #1165.

- Herrera, L., Lee, R., Longaray, J., et al. (2010). Edge Loading Wear due to Inclination Angle for Three Contemporary Hip Bearings. 56th Annual ORS Meeting. Poster #2259.

- Philippot R, Camilleri JP, Boyer B, Adam P, Farizon F. The Use of a Dual-Articulation Acetabular Cup System to Prevent Dislocation After Primary Total Hip Arthroplasty: Analysis of 384 Cases at a Mean Follow-Up of 15 Years. International Orthopaedics (SICOT) 2009; 33: 927-932.

- Stryker Test Report: RD-10-073. Range of motion and two and three dimensional jump distance of the Modular Dual Mobility Insert. September, 2010.

- Essner A, Polineni VK, Wang A, Stark C, Dumbleton JH. Hip simulator wear of “enhanced” UHMWPE acetabular inserts. Presented at: Orthopaedic Research Society (ORS) Annual Meeting; March 16-19, 1998; New Orleans, LA.

- Fatigue Comparison of Various UHMWPE for Hip Applications. Stryker Internal Report #RD-12-049. May, 2012.

- Yau S, et al. Sequential Irradiation and Annealing of Highly Crosslinked Polyethylenes Resists oxidation without sacrificing Physical/Mechanical Properties. 51st Annual Meeting of the Orthopedic Research Society. Poster No. 1670.

- Longaray et al. (2013). Fatigue and Wear Characterization of Various Contemporary Hip Bearing Materials. ORS Annual Meeting: Poster #1779

- Barlow BT, McLawhorn AS, Westrich GH. The cost-effectiveness of dual mobility implants for primary total hip arthroplasty: a computer-based cost-utility model. J Bone Joint Surg Am. 2017;99(9):768-777. doi:10.2106/JBJS.16.00109

- Abdel MP, Miller LE, Hanssen AD, Pagnano MW. Cost analysis of dual-mobility versus large femoral head constructs in revision total hip arthroplasty. J Arthroplasty. 2019;34(2):260-264. doi:10.1016/j. arth.2018.09.085

- Epinette, J.A., et al. Cost-effectiveness model comparing dual-mobility to fixed-bearing designs for total hip replacement in France. Orthop Traumatol Surg Res, 2016. 102(2): p. 143-8

- Abdel, M.P., et al. Cost analysis of dual-mobility constructs in revision total hip arthroplasty: a European payer perspective. Orthopedics. 2020 Jul 1;43(4):250-255. doi: 10.3928/01477447-20200625-01.

- Tarazi JM, Salem HS, Ehiorobo JO, et al. Minimum 7-year outcomes of dual mobility acetabular cups in total hip arthroplasty patients. J Hip Surg. 2020;04(02):090-093. doi:10.1055/s-0040-1713109

- Dubin JA, Westrich GH. Lack of early dislocation for dual mobility vs. fixed bearing total hip arthroplasty: A multi-center analysis of comparable cohorts. J Orthop. 2020;21:1-5. doi:10.1016/j.jor.2020.02.006

- Li WT, Kozick Z, Sherman M, Restrepo C, Smith EB, Courtney PM. Dual mobility bearing articulations result in lower rates of dislocation after revision total hip arthroplasty. J Am Acad Orthop Surg. Accepted manuscript. Published online December 4, 2019. doi:10.5435/JAAOS-D-19-00532. doi:10.5435/JAAOS-D-19-00532

MDMX3-WC-1_34454