Product design and lifecycle management

We recognize that our products, throughout their lifecycle, leave a footprint on our world and we are working to reduce the impact. Our Sustainability Solutions division, Research and Development and GQO teams worldwide use environmentally responsible materials and practices where possible, supporting sustainability, improving safety and meeting customer requests for more sustainable products.

Stryker has developed a comprehensive program to drive the environmentally compliant design and management of our products and packaging. We have established company-level processes to ensure that product designs meet applicable global regulations and standards and the required safety and quality standards set by regulatory agencies. Our product environmental procedures and our Regulated Substances List (RSL) ensure that compliance with restricted substance regulations such as RoHS and REACH, eliminating chemicals of concern, environmentally sound management of our products at end of life and energy efficiency are all integral components of the product development process.

We design our new product launches according to the latest regulations and standards and review existing products according to an established process. SASB

Stryker’s Sustainability Solutions

Stryker’s Sustainability Solutions division is the leading provider of reprocessing and remanufacturing services for single-use medical devices. Hospitals utilize our advanced collection system to collect devices. We inspect, clean, test, sterilize and package the medical devices for repeated safe clinical use. More than 21 types of devices are collected and reprocessed, diverting the waste from landfills, helping to support a circular economy. Over the past five year Sustainability Solutions has helped customers save $988 million and divert 25 million pounds of waste from the landfill. SASB

Over the past five years:

$988M

saved by customers through reprocessing programs

25M lbs.

waste diverted from landfills

In 2020, Sustainability Solutions launched Redesigned for Sustainability, an initiative to make environmental improvements throughout the entire reprocessing lifecycle. The focus is on six priority areas: sourcing, manufacturing, component design, material and chemical use, waste solutions and packaging. Developed with input from our customers, Redesigned for Sustainability is our commitment to deliver exceptional products that have less impact on the environment. As part of the initiative, internal new product development teams receive education on incorporating sustainable design into projects, taking into account the device’s entire lifecycle.

The reprocessed MyoSure tissue removal device is our flagship device that incorporates our Redesigned for Sustainability principles. We have made substantial environmental improvements in three areas:

Component design

• Replaced a traditional plastic component on some models with bio-based plastic

• Replaced Polyvinyl chloride (PVC) tubing with PVC-free tubing

Packaging

• Reduced packaging weight by 34 percent compared to the original packaging

• Increased recycled content and recyclability of packaging

Manufacturing

• Reduced water used in the batch cleaning process by 164 gallons

As part of their 2025 goals, Sustainability Solutions is committed to evaluating all new products coming through the new product development pipeline using the Redesigned for Sustainability initiative. They will also work to reduce their manufacturing waste by 20%.*

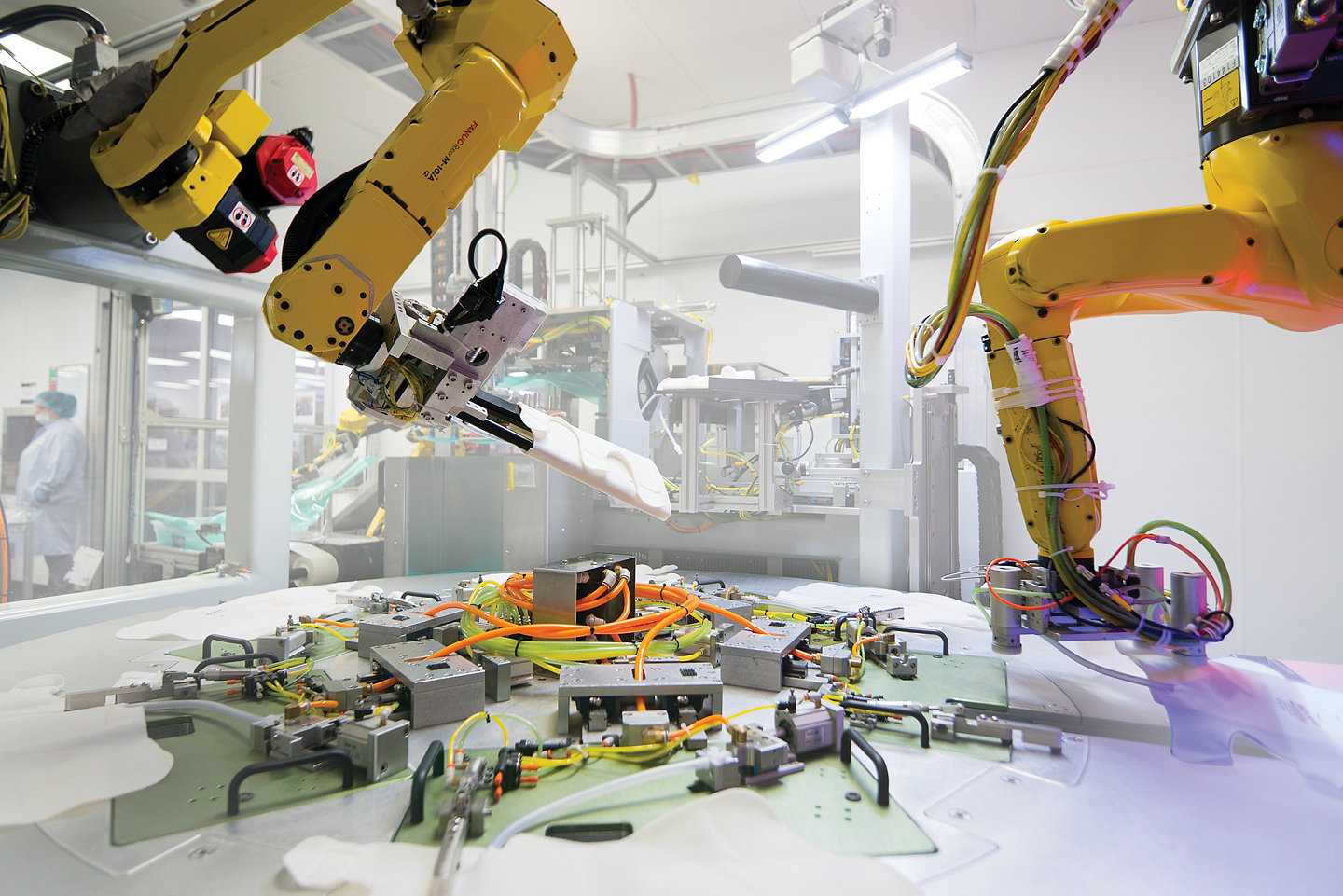

Additive Manufacturing

Another example of innovative product design is Additive Manufacturing (AM), also known as 3D Printing. AM provides design freedom for new medical devices far beyond traditional processes, and Stryker has developed new implant products across multiple divisions utilizing the technology. Stryker is recognized in the medical device industry as a leader in scaling the implementation of AM.

In 2020, we initiated a lifecycle analysis of the two production processes to calculate and define the sustainability benefits of our additive manufacturing process. To further define and promote the environmental benefits of AM over traditional methods of manufacturing, Stryker joined the Additive Manufacturing Green Trade Association (AMGTA) in 2020. The AMGTA is a global trade group created to promote the environmental benefits of AM, and Stryker is one of twelve leading companies to have joined the organization to advance sustainability in AM.

*Baseline year 2019