Environment

As a healthcare company, we know that we make choices that affect the health of the planet, and ultimately, human health. That is why, in 2020, we elected to set several bold new goals, including to achieve a 20 percent reduction in carbon emissions (scopes 1 and 2) by 2024 and to be carbon neutral for all Stryker facilities (scopes 1 and 2) by 2030.

© Brookfield Renewable Ireland

Guided by our Environmental, Health and Safety (EHS) Policy, we are in the process of aligning or certifying our facilities to the ISO14001 standard, with 13 certified as of the end of 2020. And our newly implemented EHS software management system is enabling the consolidation and tracking of data globally. We anticipate that these improvements will enable us to report consolidated environmental performance metrics in 2021.

The vice president, global manufacturing and operations (GQO), oversees our manufacturing operations facilities. Each facility is responsible for its EHS compliance which is managed by an assigned EHS point of contact (POC) who also supports the GQO EHS program. The GQO EHS director, sustainability director and regional managers support the EHS POCs. The sustainability director reports to the vice president of quality assurance and is responsible for developing and implementing the strategy to manage and reduce the environmental impact of Stryker’s value chain, including climate-related issues. 103-2

To achieve our carbon emission goals, we know we have work to do. Our carbon reduction commitments will largely be met through continued energy efficiency investments and increasing renewable energy use through long-term power purchase agreements. We are actively pursuing these opportunities through continued investment in:

- Installation of more energy-efficient LED lighting in strategic locations

- Temperature/humidity modifications and air exchanges in cleanrooms

- Occupancy sensors in offices and common spaces to control lighting

- Transitioning electricity usage to more renewable energy sources

- Redirecting waste heat from operations to reduce natural gas usage for water heating

- Energy audits to identify areas of opportunity for conservation

Highlights of our energy efficiency/conservation efforts in 2020 or planned for 2021 include:

Tullagreen, Ireland. Utilized reject heat from site chiller process to offset natural gas usage. Offset 85 percent of natural gas consumption at this site and reduced over 200 tons of carbon emissions.

Arroyo, Puerto Rico. Installed new air handling units and resin dryers, and modified the reheat coils modulation. The annual carbon emission reduction is estimated to be over 220 tons.

LED lighting retrofit/occupancy sensors. Replaced existing manufacturing floor lighting with LED retrofits/occupancy sensors in Mahwah, New Jersey and Fort Lauderdale, Florida, among other sites.

Effective energy-efficiency improvements and conservation efforts alone will not get us to our goal. Renewable energy sourcing is critical to our ability to meet this goal. We recently signed a renewable energy power purchase agreement to supply 100 percent of our electricity for our GQO Ireland sites with renewable energy. Additionally, we use a majority hydroelectric energy at our GQO sites in Germany. Altogether, renewable sources now generate about 15 percent of our electricity use at GQO sites. Going forward, we are exploring additional power purchase agreements to meet our carbon reduction goals.

GQO sites in Germany powered by hydroelectric energy

We have established a 2019 baseline for our scopes 1 and 2 carbon emissions and our goals for scopes 1 and 2 are based on the Science Based Target initiative (SBTi) guidelines. We are committed to establishing a scope 3 emissions baseline in 2021 and setting and disclosing a science-based target.

We have initiated a review of our climate change risks and opportunities and anticipate future reporting will include recommendations developed by the Task Force on Climate-related Financial Disclosures (TCFD) in four areas: governance, strategy, risk management and metrics and targets.

Stryker publicly reports GHG emissions data and reduction initiatives annually through the Carbon Disclosure Project (CDP). CDP is an internationally recognized nonprofit organization that collects and reports environmental metrics. Currently, Stryker reports its direct and indirect energy use and emissions from our manufacturing operations and business travel. In 2020 Stryker received a C score from the CDP.

Stryker is committed to the protection of our environment through the elimination of waste. Historically, we have focused on source reduction, waste minimization and recycling improvements. To fully understand the waste generated from our manufacturing processes, we monitor and measure the waste generated throughout the GQO network. We use waste generation data to drive waste minimization projects locally.

In 2020, we continued our efforts to reduce both what we use and what we leave behind. We are working to verify our data collection results and establish waste reduction goals in 2021. Some of our businesses have already taken this step, Stryker’s Sustainability Solutions division has set a goal to reduce manufacturing waste by 20 percent by 2025.

In 2020, each of our manufacturing facilities had a goal to reduce their waste by 10 percent. While performance on this goal varied by plant location, many were able to make progress. Selected highlights include:

Tullagreen, Ireland

- Green waste: Approximately 75 tons disposed of at a waste-to-energy facility, avoiding landfill.

- Process sludge: Approximately 30 tons processed to make eco-concrete, reducing both waste product being landfilled and the raw materials needed to make the concrete.

Limerick, Ireland

- Process sludge: Reduced waste product disposed of by 70 percent by removing water content, enabling the remaining sludge to be sent for energy recovery.

Mahwah, N.J., U.S.

- Waste plastic chips: Shipped to another company for use as a raw material.

Anngrove, Ireland

- Food waste: Diverted three tons of composting food waste from landfill to energy recovery.

- Argon reduction: Reduced argon use in LRM manufacturing by 41 percent through standardization of equipment settings.

We recognize that water is a precious resource that must be conserved and protected. We use water to create our products and cool equipment, and we monitor our wastewaters, as required.

Water reclamation and reuse initiatives can provide cost savings, improve environmental performance and reduce compliance risk through minimization. Water consumption and water discharge data are collected to understand our impacts and opportunities better. In 2020, we began work to set a baseline for our water use to allow for more efficient tracking and reporting in future years.

Transportation of our products is a component of our scope 3 carbon emissions, and one we are focused on reducing. In 2020, Stryker took the opportunity to examine shipping processes, which resulted in a shift to more sustainable modes such as sea freight. We also implemented a regular evaluation of our supply chain networks to ensure shipments are sent via the most direct routes to the end customers, ultimately driving fewer trips. Another successful effort involved direct shipping product from Thailand to the U.S. using ocean freight; we achieved a 99 percent decrease in carbon emissions by eliminating the previous airfreight route which shipped through our European Distribution Centre.

Approximately 300 carriers are used to move our products around the globe, and we’re focused on rationalizing this base to include the most carbon-efficient providers. Going forward, we continue to optimize our transportation networks, focusing on the continued reduction of carbon emissions. Opportunities include network assessments, collaborating with our product development teams to fully utilize the space in our boxes to reduce packaging; partnering on carbon reduction initiatives such as UPS’s Carbon Neutral program, in which Stryker’s Sustainability Solutions division participates; and joining programs such as the U.S. EPA SmartWay program, which we initiated in 2020.

Certifying our facilities

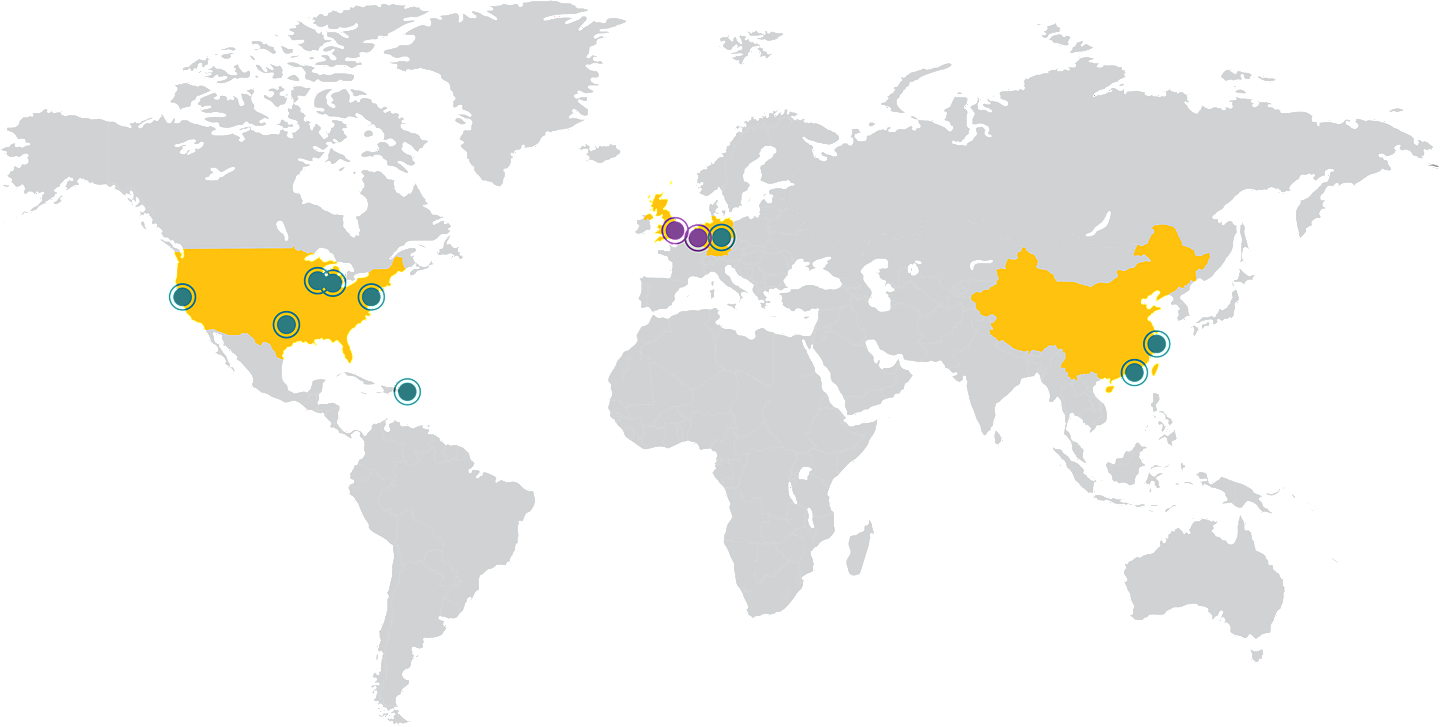

Our offices and manufacturing facilities have an impact, too, and we are working with accrediting organizations to evaluate and certify the environmental impact and sustainability of our buildings. The following Stryker locations have been certified by Leadership in Energy and Environmental Design (LEED), a green building rating system, and Building Research Establishment Environmental Assessment Method (BREEAM), a sustainability performance rating system:

LEED:

Suzhou, China

Portage, MI, U.S. (3)

Mahwah, NJ, U.S.

Cary, IL, U.S.

Flower Mound, TX, U.S.

Arroyo, Puerto Rico, U.S.

San Jose, CA, U.S.

Hong Kong, China

Freiburg, Germany

BREEAM:

Venlo, Netherlands

Newbury, Berkshire, U.K.

A new Instruments facility, located in Portage, Michigan, features a customer experience center, a showroom, an R&D and bio-skills lab, plus space for sales, marketing and support functions. The space, which inspires innovation, also meets LEED Silver certification status, making the new facility a physical depiction of living our company’s mission.