Patient safety

25-Jan-2021

One of the primary goals of healthcare is to use the power of modern medicine and quickly-advancing technology to help improve the quality of peoples’ lives. From sterilization to operation, achieving the best performance in the operating room by using the right technology and techniques must be a top priority for every surgeon.

Hospitals recognize that delivering the highest quality healthcare requires using the most advanced and state-of-the-art technology on the market. That includes surgical blade technology.

Over the years, the power tools used in the operating room have advanced and adapted to modern healthcare and evolving patient needs. The same is true for surgical blades.

The difference between surgical blades may seem small and inconsequential, but in an industry that focuses on the details and accuracy, these small details may have big impacts. Cutting technology has advanced greatly in recent years, and hospitals would do well to invest in acquiring these new tools.

In this article, we will describe some of the ways that surgical blade technology has advanced and how new blade technology could help enhance healthcare.

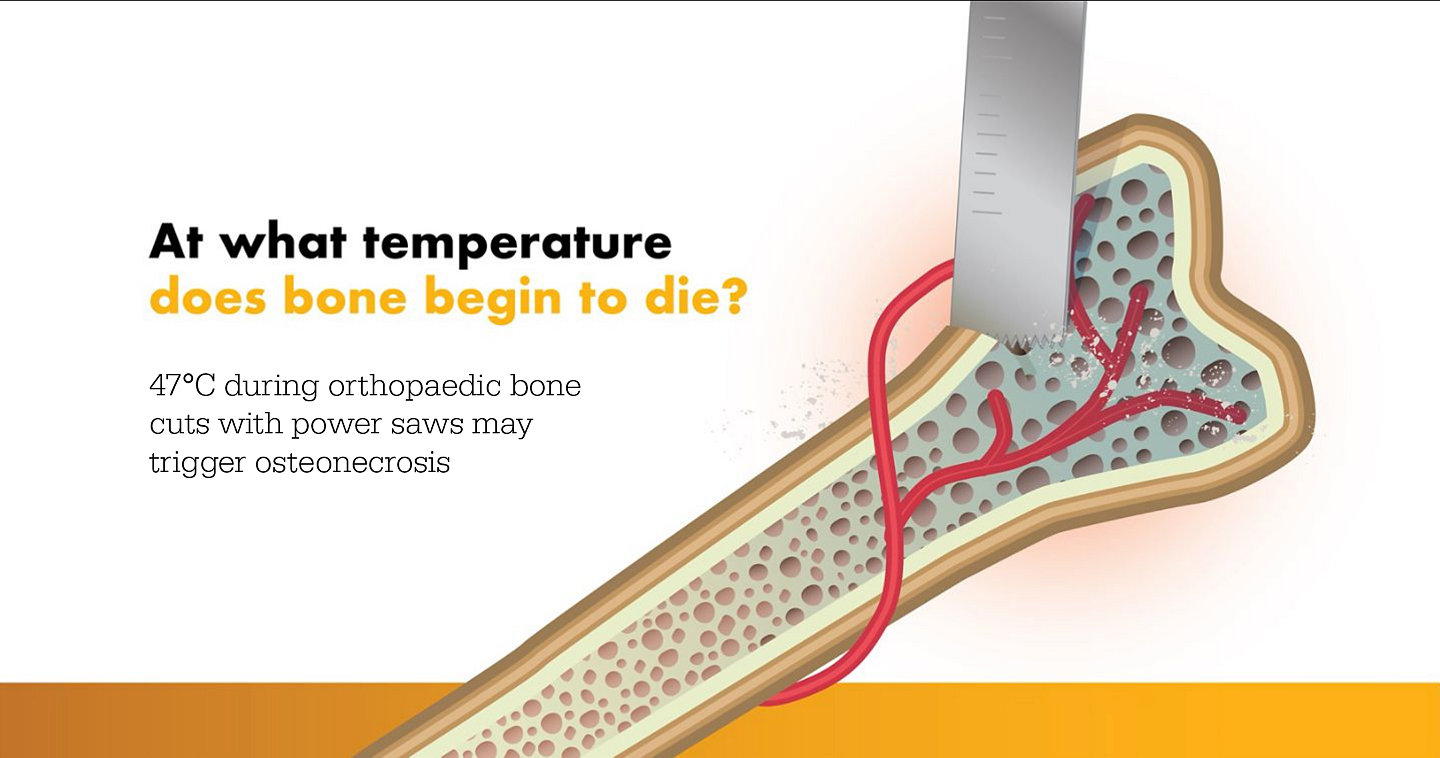

In this section, we’ll look at two aspects of orthopaedic blades: cutting temperature and blade control. We’ll see how improvements in blade and tool design could potentially impact bone health from surgery by reducing cutting temperature and enhancing blade control.

Bone temperatures above 47°C (116.6˚F) during orthopaedic bone cuts with power saws may trigger osteonecrosis. Factors such as the duration of time that the blade is in use could lead to a damaging amount of heat being transferred into the cut site.1

The blade assembly and adherence to the recommended duty cycles are a few factors that can play a significant role in determining the amount of heat that’s generated while cutting, and the speed of cutting determines how long the bone is exposed to that heat.

Humanity has developed different tools over time to suit our human needs. For example, we have butter knives to spread butter and steak knives to cut steak. Now, the butter knife can still cut through steak, but it will require much more time, effort and cutting on your part to do the job that a steak knife could do more quickly and effectively.

This is essentially what would happen in operating rooms across the world if surgeons did not choose the right blade for the job. When choosing a knife for dinner, you exercise conscientiousness. Similarly, surgeons need to be highly conscientious of their choice in tools and should be looking for blades that are specifically designed to help them manage speed and cutting temperature.

Stryker’s Precision oscillating tip saw has two speeds, standard (12KCPM) and fast (16KCPM). Its stationary blade shaft is designed to improve visibility for the surgeon, reduce potential of damage to surrounding tissue and makes it ideal for MIS (minimally invasive surgery).

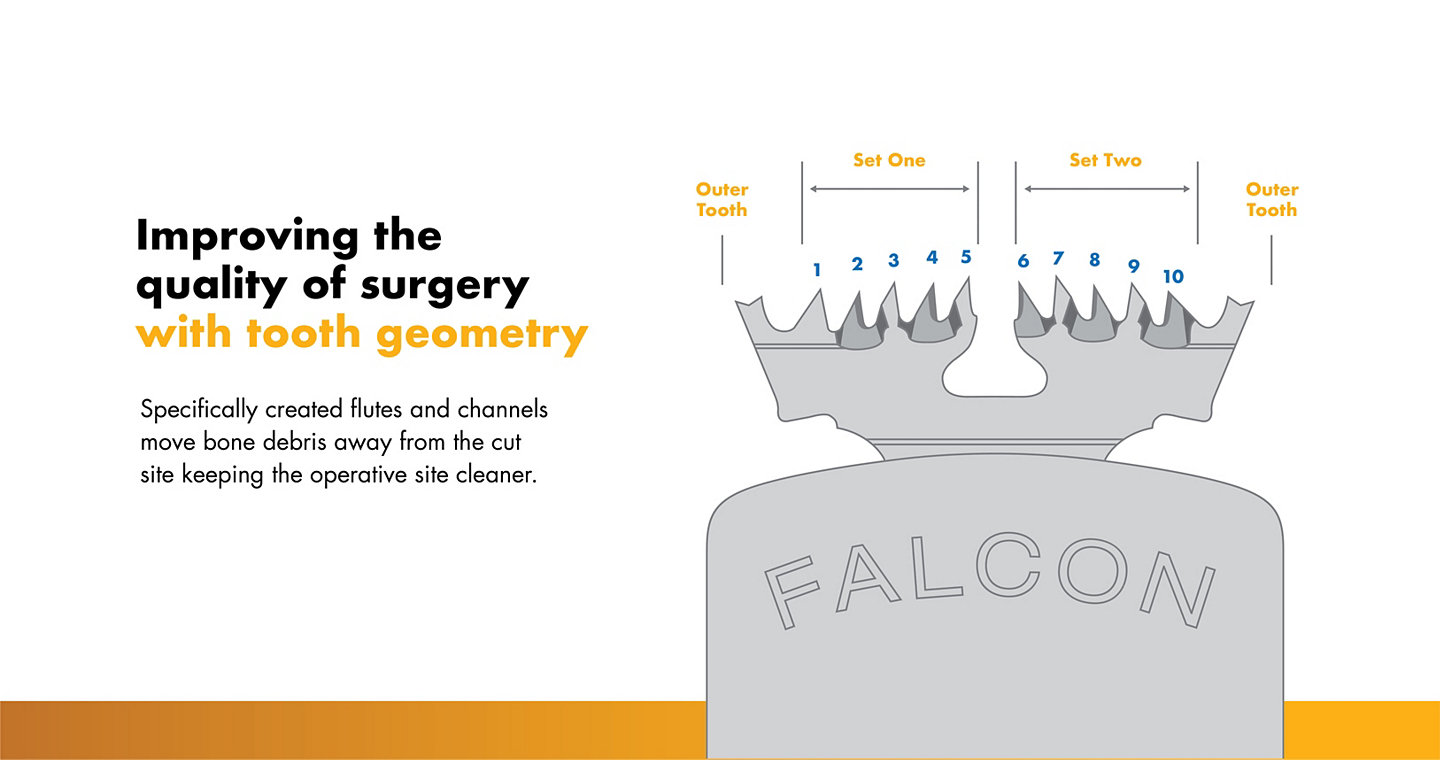

The Precision Falcon cartridge blade, combined with the speed on Stryker’s Precision oscillating tip saw, cuts quickly and contributes to a stiffness increase by 30% that gives increased control.2 This combination of saw and blade can lead to better results for accuracy and speed.

Blades may seem simple and, ultimately, their intended purpose is fairly rudimentary, but many blades, especially those used in surgery, have very complex designs and functions. The type of blade tooth geometry, the blade length, operation, speed, removal of debris and other factors drive the choice of blades and tools.

Surgery is an exact science, and when considering a blade that will be used in the operating room, it’s essential that the blade obeys the surgeon in exactness and in motion. Important aspects of cutting control are excursion and precision.

Excursion is a term that’s used to describe the range of repeated movement in a medical device, like a surgical blade. Excursion can impact blade control. For example, think about an electric toothbrush which has a very low level of excursion. It’s relatively easy to control inside your mouth and you can be very quick and accurate, getting it exactly where you want it to go. Now, think about an industrial jackhammer, which has a much larger excursion and is much harder to control.

In a sense, the same idea is true for surgical blades. A toothbrush and an industrial jackhammer are used for different jobs and can both be incredibly effective when used in the right context. In the same way, a blade with a larger excursion can be helpful in certain operations, while a blade with a smaller excursion is valuable for others.

A study evaluating accuracy and excursion of blades (the extent of blade movement) used for total knee arthroplasty (TKA) compared results from two types of blades: a conventional oscillating saw blade (Stryker’s system 6 sagittal saw), and an oscillating tip saw blade (Stryker’s Precision sagittal saw).3

The study’s key indication is that excursion is related to the saw blade length and the distance of the oscillation from the end of the blade.

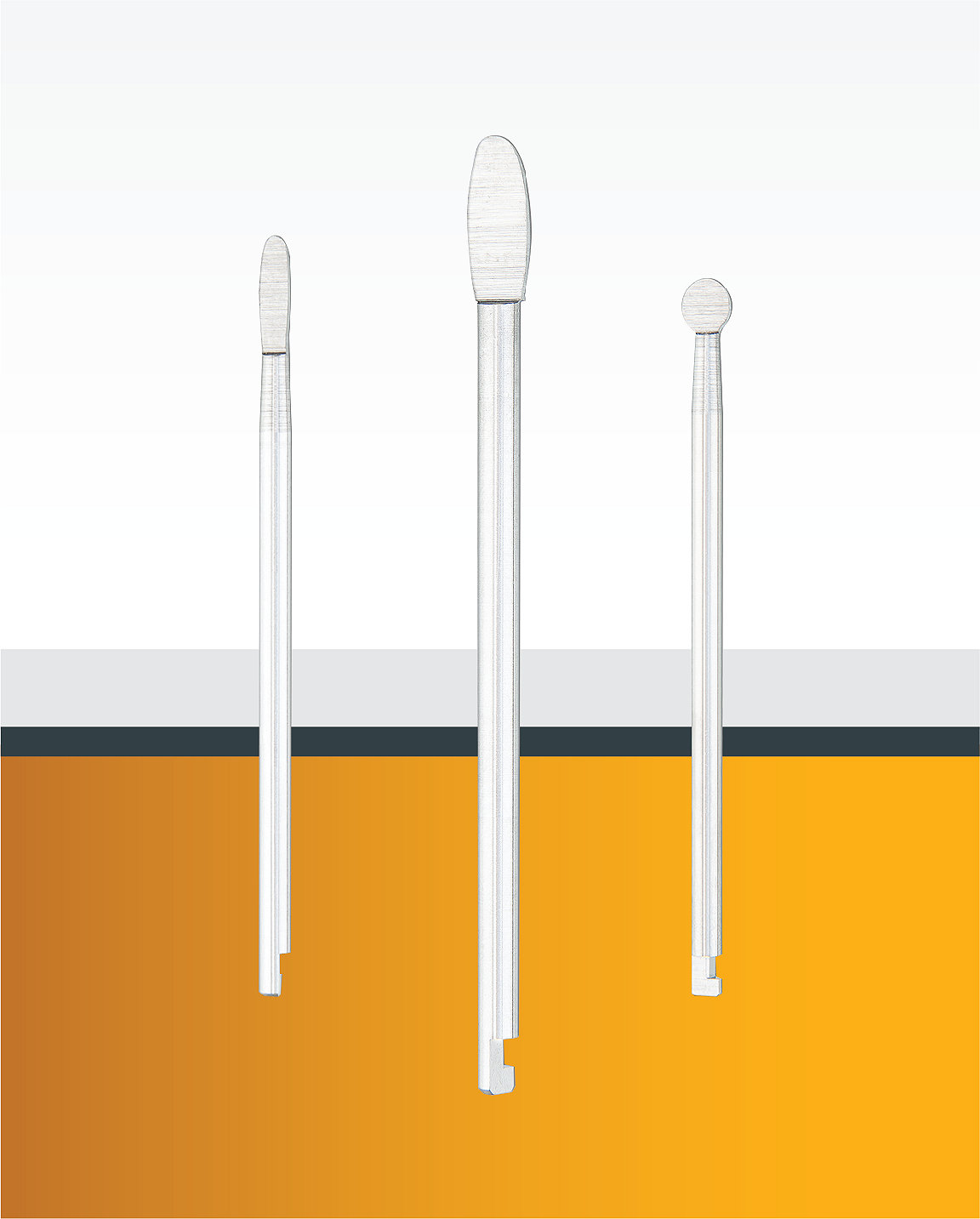

Performance Series Blades

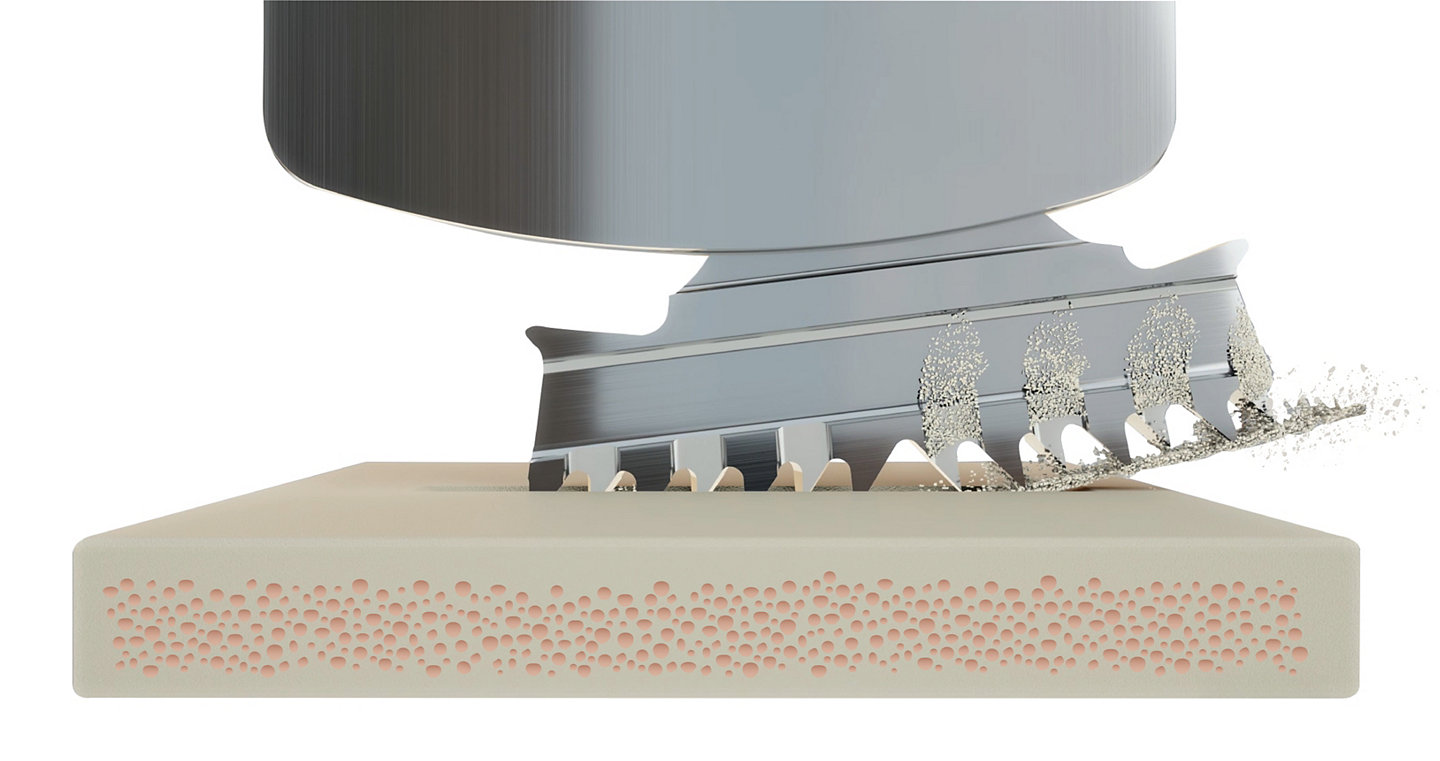

Chip Clearance

Stryker Precision Oscillating Tip Saw

Chip Clearance

The study evidenced that the conventional saw blade oscillates from the hilt of the saw, while the oscillating tip saw evidenced less excursion. Additionally, the study used dye to measure the effect of the blades on the surrounding tissue. Minimal dye markings left by the oscillating tip blade suggested less impaction for the soft tissue around the knee, which could allow for a more straightforward recovery.

The study suggests better outcomes are possible with minimal excursion since damage to the soft tissue like the extensor mechanism, neurovascular bundle, and medial collateral ligament during a TKA procedure can lead to complete joint failure.

Incidentally, the oscillating tip saw system has been measured to be quieter than the conventional oscillating saw blade system, making surgery safer for the surgical team as well.4

A recent study compared the debris generated in surgical procedures with different tools. The study, using porcine cadaveric knee joints, was designed to approximate TKA, and one experienced orthopedic surgeon performed all resections.5

This study compared two cutting systems: System 5 sagittal saw with the standard dual-cut oscillating blade, and the System 6 oscillating tip saw with Stryker Precision oscillating tip cartridge.

Metal debris was carefully collected and measured after each simulated TKA, and for the standard dual-cut oscillating blade averaged 12.741mg. According to the study, the Stryker Precision oscillating tip cartridge procedures averaged 2.021 mg of debris, an 84% reduction.

%2020?$max_width_1440$)

The study also suggests the oscillating tip saws could help keep surgeons from accidentally hitting the metal guards or blocks, which can create metal debris. This improved saw system provides measurable gains in instrument control. Although this was a cadaveric study in nature, it does illustrate that risks to the patient can be reduced with the best tools and risk controls measures in place.

The study suggests that the type of blade (and saw) used is a major factor in just how much metal debris is generated. Minimizing debris is important because of the difficulty of removing metal debris from a joint site during actual surgery. Wayward debris can easily enter the joint and increase joint wear, as well as lead to bone loss.6

Every surgeon aims to maximize performance excellence in the operating room. Choosing the best surgical tools for the job is a necessary part of that aim. Stryker’s tools can help with that.

[1] Augustin G, Zigman T, Davila S, Udilljak T, Staroveski T, Brezak D, Babic S. Cortical bone drilling and thermal osteonecrosis, Clin Biomech (Bristol, Avon). 2012 May;27(4):313-25. https://www.ncbi.nlm.nih.gov/pubmed/22071428.

[2] https://pdf.medicalexpo.com/pdf/stryker/system-7-precision/70192-129312.html, accessed January 15th, 2020.

[3] Wetzel RJ, Shah RR, Puri L. Demonstration of saw blade accuracy and excursion: a cadaveric comparions study of blade types used in total knee arthroplasty. J Arthoplasty, 2013 Jun;28(6):985-7. https://www.ncbi.nlm.nih.gov/pubmed/23523505

[4] Peters MP, Feczko PZ, Tsang K, van Rietbergen B, Arts JJ, Emans PJ. Noise exposure in TKA surgery; oscillating tip saw systems vs. oscillating blade saw systems, J Arthroplasty. 2016 Dec;31(12):2773-2777, https://www.ncbi.nlm.nih.gov/pubmed/27394075.

[5] Gotterson PR, Nusem I., Pearcy MJ, Crawford RW. Metal debris from bony resection in knee arthroplasty – is it an issue? Acta Orthopaedica 76, no. 4 (2005) https://www.tandfonline.com/doi/full/10.1080/17453670510041448.

[6] Sarah E. Sydney, BEng; Simon A. Pickering, MD, FRCS (Eng), FRCS (Orth); Cameron G.R. Bell, PhD; Ross Crawford, MBBS, FRACS, DPhil (Oxon). Reducing Metal Debris Generation During Total Knee Arthroplasty. Orthopedics, 2007; 30(12): 999-1000. https://www.healio.com/orthopedics/knee/journals/ortho/2007-12-30-12/%7B03131112-b352-4ee1-9103-4b7d7b79f546%7D/reducing-metal-debris-generation-during-total-knee-arthroplasty

D0000023495 Rev AB / Smacc 2021-28366